Portfolio Details

BYD Song PLUS Project Overview

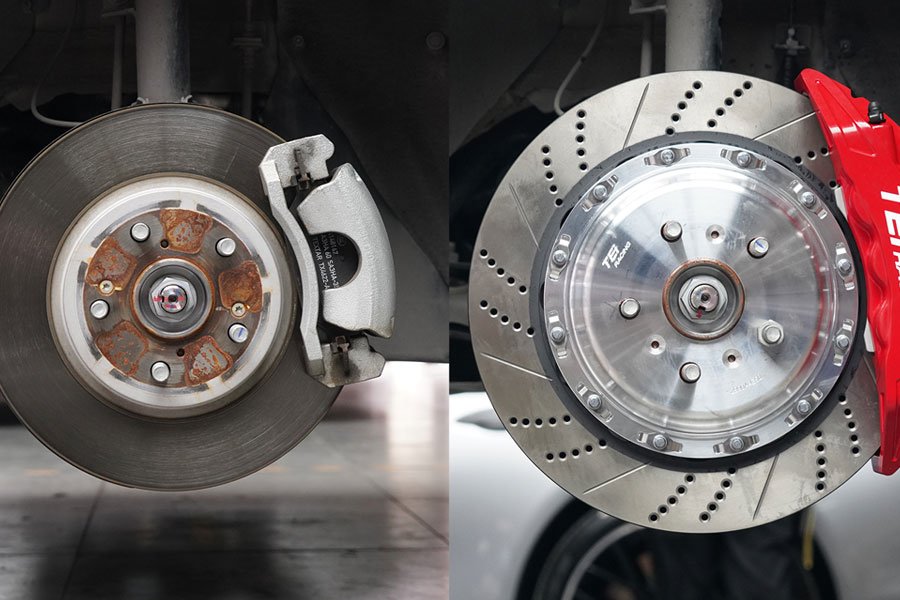

Upgrading the braking system is critical for both high-performance and commercial vehicles, as it directly impacts safety and vehicle lifecycle costs

Our client—a major fleet management company in Stuttgart—sought to reduce maintenance downtime and enhance vehicle safety margins under heavy-duty, repeated braking cycles.

- Vehicle model: BYD Song PLUS

- Caliper Pistons: 6 Pistons Cast Two Piece Aluminum Alloy

- Disc: 380x28mm Punched Marking Split Disc

Our Solution

We delivered a turnkey upgrade package covering component design, validation, and in-field support:

- OEM Bridge Code

- Custom Caliper

- Disc Center hub

- Installation Fitment Optimization

- Caliper oil circuit and oil pipe sealing test

- High-Temperature Performance Testing

Results

Post-upgrade data and client feedback demonstrated:

Up to 13-Foot Reduction in Stopping Distance

Measured in ABS emergency stops from 62 mph, consistent across dry, wet, new, and worn tire conditions

Elimination of Pad & Rotor Wear

PVD-coated (“PureForge”) rotors ran with negligible wear and generated significantly less dust, cutting pad replacement costs by over 20%

Dramatically Improved Fade Resistance

No significant increase in rotor temperature after 50 repeated stops, versus a 15% performance loss on OEM units

Enhanced Driver Confidence

Operators reported more consistent pedal feel under heavy-load braking and reduced stopping variability, boosting operational safety.